|

|

CPM S30V

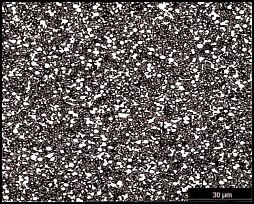

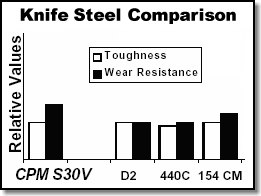

The following information has been adapted from the Crucible Materials Corporation Web site and Data Sheets for CPM S30V. It provides some technical comparisons to other common high-end knife steels and can explain, to a degree, why CPM S30V excels. CPM S30V is a martensitic stainless steel designed to offer the best combination of toughness, wear resistance and corrosion resistance. Its chemistry has been specially balanced to promote the formation of vanadium carbides which are harder and more effective than chromium carbides in providing wear resistance. CPM S30V offers substantial improvement in toughness over other high hardness steels such as 440C and D2, and its corrosion resistance is equal to or better than 440C in various environments. The process of producing CPM (Crucible Particle Metallurgy) steels involves gas atomization of pre-alloyed molten steel to form powder. This powder is then screened and then isostatically compressed into 100% dense compacts. The CPM process produces steels withe no alloy segregation and extremely uniform carbide distribution characterized by superior dimensional stability, grindability, and toughness compared to steels produced by conventional processes.

Crucible CPM S30V Alloy Composition

Although the longitudinal toughness for all three of these grades is about 25-28 ft. lbs., the transverse toughness of CPM S30V is four times greater than that of 440C or 154CM. These higher transverse toughness results indicate that CPM S30V is much more resistant to chipping and breaking in applications which may encounter side loading. In knifemaking, its higher transverse toughness makes CPM S30V especially good for bigger blades. Edge Retention (CATRA Testing Relative to 440C)

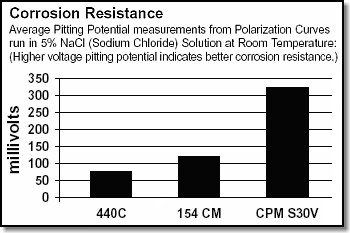

The CATRA (Cutlery & Allied Trades Research Association) test machine performs a standard cutting operation and measures the number of silica impregnated cards which are cut (TCC = total cards cut). It is considered a measure of relative wear resistance. Corrosion Resistance Average Pitting Potential measurements (below) from Polarization Curves run in 5% NaCl (Sodium Chloride) Solution at Room Temperature: (Higher voltage pitting potential indicates better corrosion resistance.)

Note: Properties shown are typical values. Normal variations in chemistry, size and heat treat conditions may cause deviations from these values. | |||||||||||||||||||||||||||||||||||||||||||||

Doug Ritter and the Doug Ritter logo are trademarks of Doug Ritter, LLC

© 2004 Douglas S. Ritter - All rights reserved

http://www.DougRitter.com/pop_up_cpms30v.htm

Toughness (Transverse Charpy C-notch Testing)

Toughness (Transverse Charpy C-notch Testing)